Vacuum trucks, also called the Vac trucks, are versatile vehicles used by municipalities or towns for cleaning streets, overflown sewers and other functions. Many people in the public recognize this tank because of the spills that have been happening and the good job these vehicles do to clean the spills. The other logical step may be to wonder how the Tankformator ISO tanks perform this important role.

The process

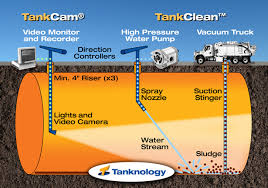

After turning on the vacuum truck tanker trailer, the twin or triple tanks blow air pressure that causes the air to flow via the intake hose and nozzle. This air goes through several chambers that include the storage tank, then goes through the micro-mesh filter system before flowing to the surrounding area.

If you desire to elaborate this procedure, taking a closer look at what takes place when the truck extracts dirt from the ground will make you understand its functionality. When the intake nozzle of the machine is directed at materials that are dry, it pulls them through the air flow into the machine. This material travels and then gets deposited into the main storage tank. Smaller particles continue travelling and get deposited in the smaller tanks. All particles of dust carried by the air flow get filtered by the micro-mesh filter system. After flowing through the system, the air will go back to the atmosphere, gets filtered and becomes clean.

Pump system info

The vacuum pump package found in every particular truck has the design of performing the work efficiently and quickly. The manufacturers place particular limits intentionally or specifications in the pump for the purpose of future monitoring for the pump system to function at normal capacity while operating.

There are two major vacuum pump package systems from the manufacturer; rotary vane and liquid ring version. The best vacuum tank for sale is dependent on business needs and application. The liquid ring version is the most populous in the industry because it is oil-free, more proficient, and not noisy in accomplishing the required tasks. The pump system for a liquid ring is intricate and has the need for more water and area for proper functionality. Conversely, the rotary version is easy to maintain but its disadvantage is that it produces a lot of smoke and noise at times.

Tank information

Tank information

The size of the ISO tanks varies and depends on the vacuum truck tanker trailer and the vacuum pump package. The tank needs to have space that is essential for storing materials. The manufacturing process of the tank requires a period of between three to twenty weeks depending on complexity. There are several diameter standards in the market that fit well on the truck and are suitable for many pump systems.

In most cases, waste material is abrasive and the velocity it uses to enter the tank contributes towards the deterioration of the tank. You can use linings on this tank but it contributes towards increasing the cost aspect. It is quite important to know that the life of the liquid waste tank does not have to be extended beyond its design either by use of linings or repair. The world leading ISO Tank Container Manufacturers, the best way of decommissioning the ISO tanks is through replacement.